Facilities list

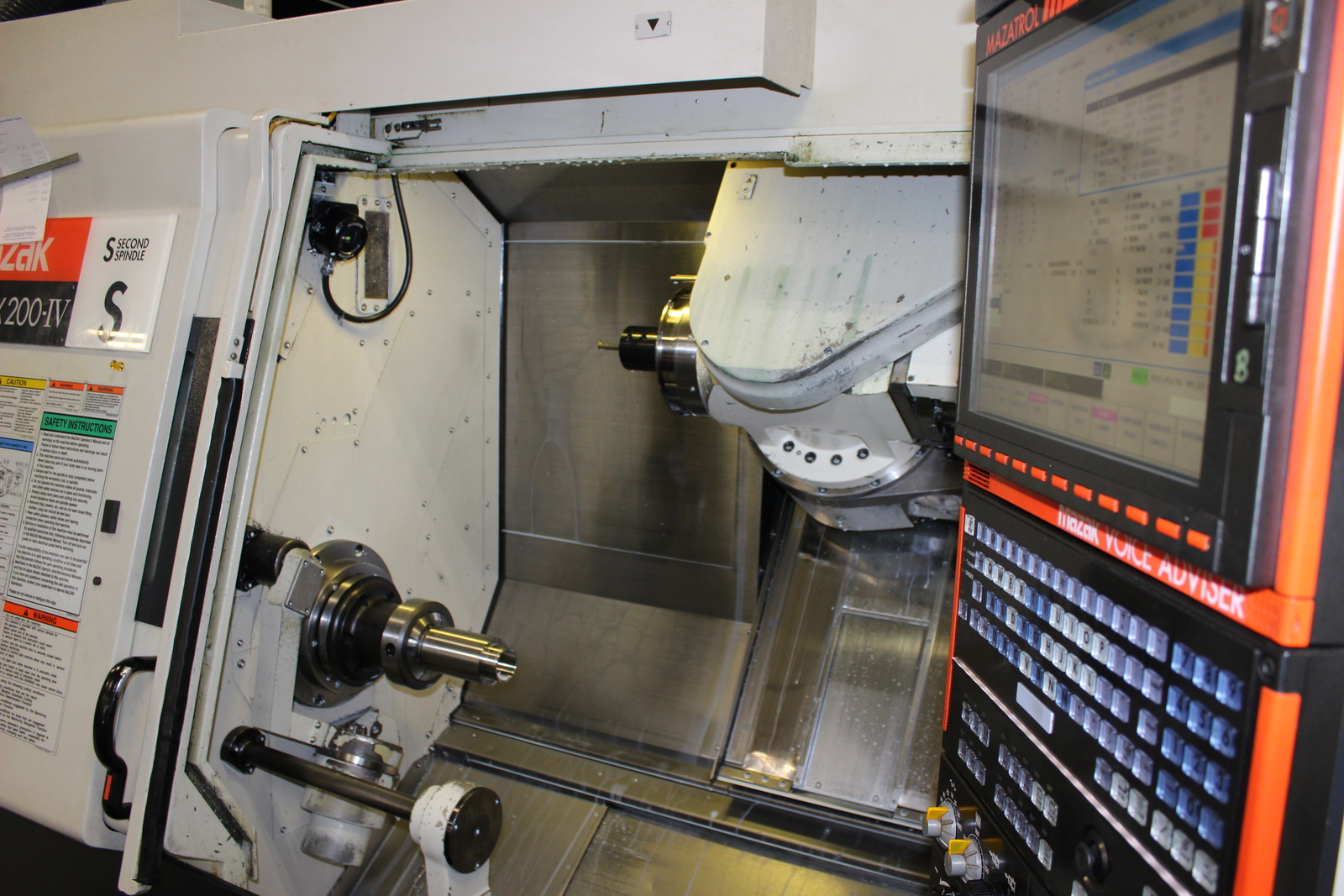

In this world of competitive manufacturing, we strive to increase our productivity and efficiency by using multi-function machine tools. We can eliminate many secondary operations by turning, milling and drilling in one set up; saving time by completing the part on one machine instead of two or more.

All of our CNC Lathes have milling capabilities and bar feeders and some lathes have sub spindles and Y axis. These features allow us to manufacturer complex parts in one complete operation.

Our CNC Mills are equipped with the latest technologies to include through spindle and high pressure coolant, rigid tapping, 4th axis and 10 millionths offset resolutions.

Swiss machining has been a focus for the last few years, recently adding large capacity Swiss to our capabilties

Equipment List

Milling

-

Two Mazak 510C Mills

- Big Plus cat 40

- 30 tool changer

- Renishaw tool probe and part measuring probe

- 4 axis table

- Table size 40 X 20 X 20 height

- 210 PSI coolant through

5 Axis Machining

Mazak Integrex I-200S

- Mazak Integrex 200IV and I-200S

- 120 Capacity, Capto 6 tool changer

- Renishaw part measuring probe.

- 2 ½” bar capacity

- 10” Swing

- 12,000 RPM spindle through coolant spindle

- .00001" resolution

- Sub Spindle

- 72 tool magazine, capto 6

- 2 1/2" bar capacity / 10" swing

- 12,000 RPM through coolant spindle

- .00001" resolution

- latest Matrix 2 control

Live tool CNC Lathes

- 6 - Mazak QT live tool lathes

- Bar work form 2-3”

- 4’ Bar-feeder on all

- Sub Spindles

- Y axis capable on two machines

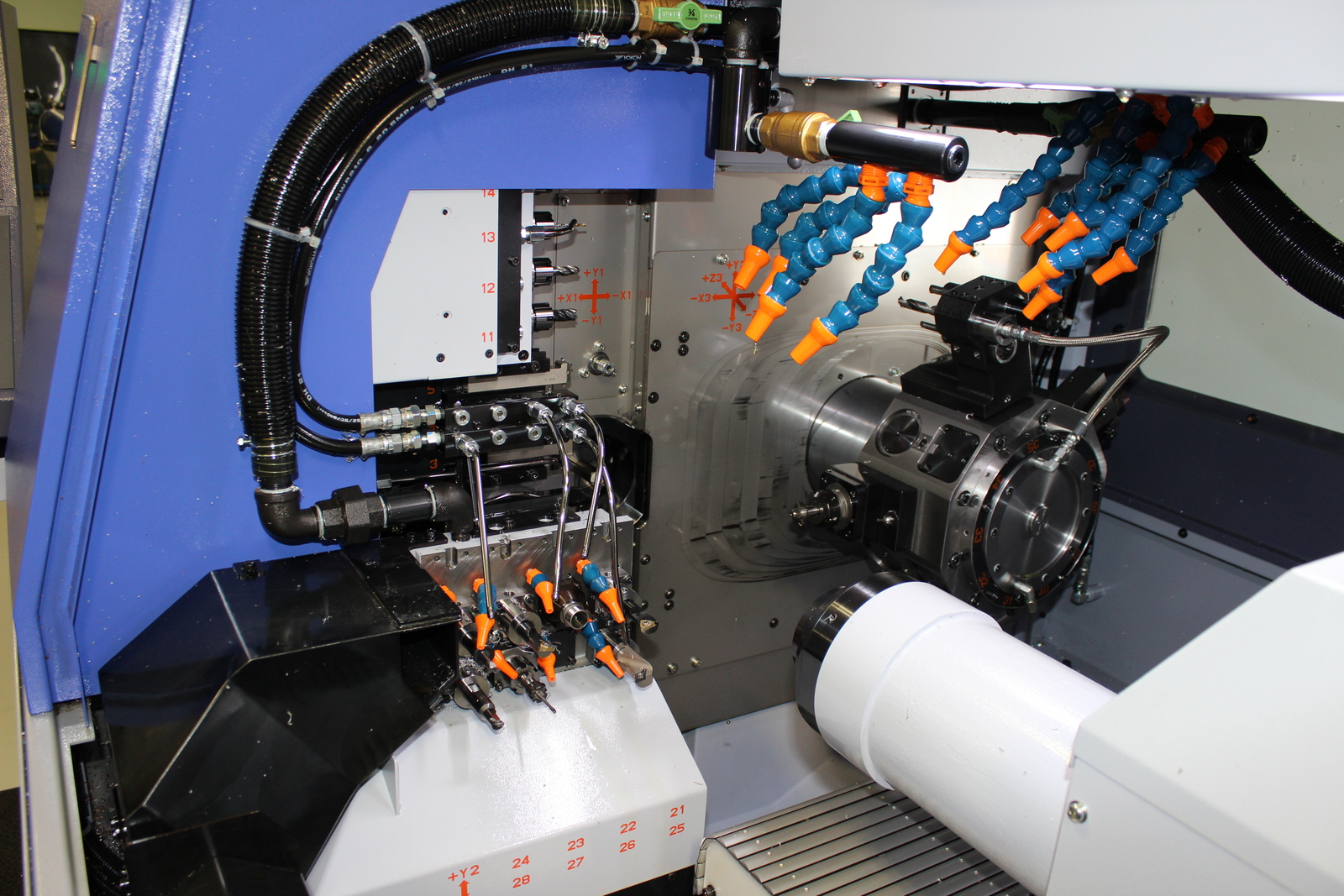

Swiss Star SR-20RIII

STar SR-20RIV

- ¾” capacity

- 12’ Bar-feeders

- 1,000 PSI

- .00001 resolution

- Live cross tools and end-working

- Sub-spindle with live or static tools

- Second machine added in 2017

- ¾” capacity

- 12’ Bar-feeders

- 1,000 PSI

- .00001 resolution

- Live cross tools and end-working

- Sub-spindle with live or static tools

Star SV-38R

- 1-1/2” bar capacity

- 5 7/8” pick off length

- .00001 Resolution

- 1,000 PSI

- Chucker mode option(non-ground bar stock)

- Pinch turn, and milling

- Full Turret, and 5 Axis capable

- 8 Station Y axis sub-spindle with Live tools

Tsugami SS20

- ¾” bar Capacity

- Chucker mode and Swiss mode

- .00001 resolution

- Live cross on main spindle

- 10 tools on sub-spindle, Y axis, live tools

Laser Marking

CNC tool Grinder

.jpg)

FLASH 302 CMM

- Keyence 3D Laser marker

- Ability to Mark steps and Spheres

- Pallet marking capable

- Anca Fast Grind CNC tool grinder

- We make special tools as needed

- We sharpen all in-house tools reducing cost and down time

- Flash 302 with Visaion and Scanning Head

- Scanning head 10X more accurate than touch probe

- We can import solid models for ease of programming

- 12 X 12 X 10 travel

Saw Cutting

- Two automatic saw 10” capacity

Tool Grinding

- Monset grinder and Endmill sharpener for in-house grinding of standard and special tools